Typical applications of radar level gauges in large chemical storage tanks

2024-10-21

As an advanced liquid level measurement technology, radar level gauge is widely used in large chemical storage tanks. This article will introduce the typical application scenarios and advantages of radar level gauges in large chemical storage tanks.

1. Typical application scenarios:

Petrochemical storage tanks: used to measure the liquid level of petroleum, crude oil, fuel oil and other products. Chemical storage tank: used to measure the liquid level of various chemicals, solvents, acid and alkali liquids, etc. Liquefied gas storage tank: used to measure the liquid level of liquefied gas, liquid ammonia, liquid oxygen and other gases.2. Technical advantages:

Non-contact measurement: The radar level gauge uses wireless signals for measurement without direct contact with the liquid, thus avoiding contamination and corrosion. High-precision measurement: It has high measurement accuracy and can meet the precise requirements of liquid level monitoring in large storage tanks. Strong adaptability: can adapt to various liquid media and harsh environments, such as high temperature, high pressure, corrosive media, etc.Related questions:

How is radar level gauge used in petrochemical storage tanks? It can be installed on the top of the storage tank to measure liquid level through radar technology to achieve real-time monitoring of oil, crude oil and other products. What are the advantages of radar level gauges in chemical storage tanks? Radar level gauges can safely and accurately measure the liquid levels of various chemicals, avoiding safety hazards caused by direct contact with liquids. Why choose radar level gauge for large liquefied gas storage tanks? The radar level gauge can stably and reliably measure the liquid level of liquefied gas, liquid ammonia and other gases. It has strong adaptability and can meet the special needs of the liquefied gas industry. What are the installation requirements for radar level gauges in large chemical storage tanks? The installation location should be selected on the top of the storage tank to avoid the impact of liquid fluctuations and agitation on the measurement results; the distance from surrounding objects should be ensured during installation to avoid affecting signal transmission and reception.Summary: Radar level gauges are widely used in large chemical storage tanks. Its non-contact measurement, high accuracy and strong adaptability provide a reliable solution for tank level monitoring, which is important for improving production. Efficiency and safety are of great importance.

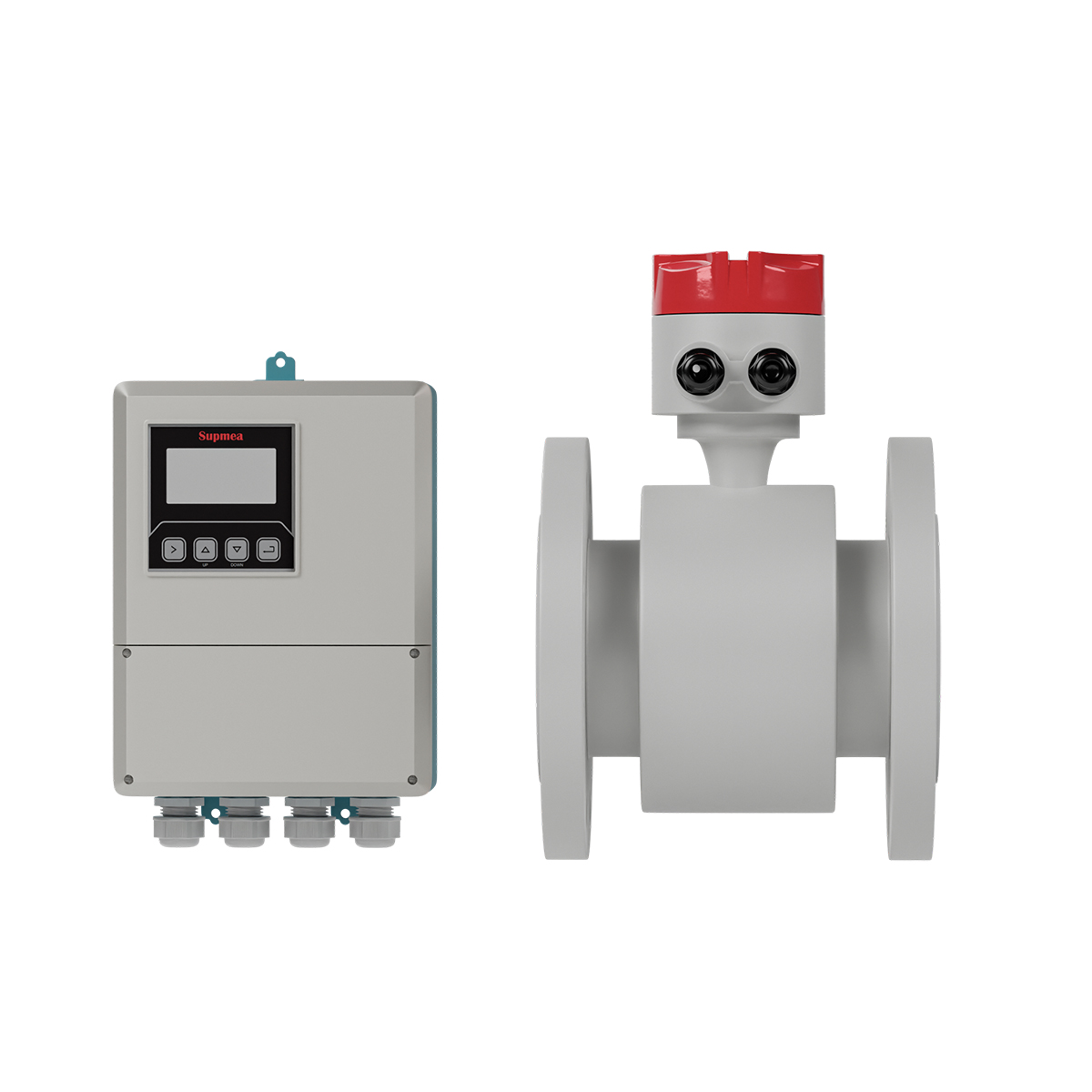

Related Products

Inquiry

Please leave us your requirements, we will contact you soon.