Selection of electromagnetic flowmeter need to consider the factors

Now in the city or industry, the discharge of sewage measurement, the vast majority of the use of electromagnetic flow meters. Electromagnetic Flowmeter high precision, long service life, is the first choice of environmental protection measurement industry. Correct selection of Electromagnetic Flowmeter, in order to ensure the use of Electromagnetic Flowmeter better, according to the chemical nature of the fluid medium, pipe caliber size, flow range, lining materials, electrode materials and output signals and so on.

First, the fluid medium can be measured

Through the principle of Electromagnetic Flowmeter, Electromagnetic Flowmeter can be selected is a conductive liquid, only conductivity greater than 5μ/cm can be selected Electromagnetic Flowmeter. However, the limitations of the Electromagnetic Flowmeter can only measure the liquid, can not measure the gas and steam and so on.

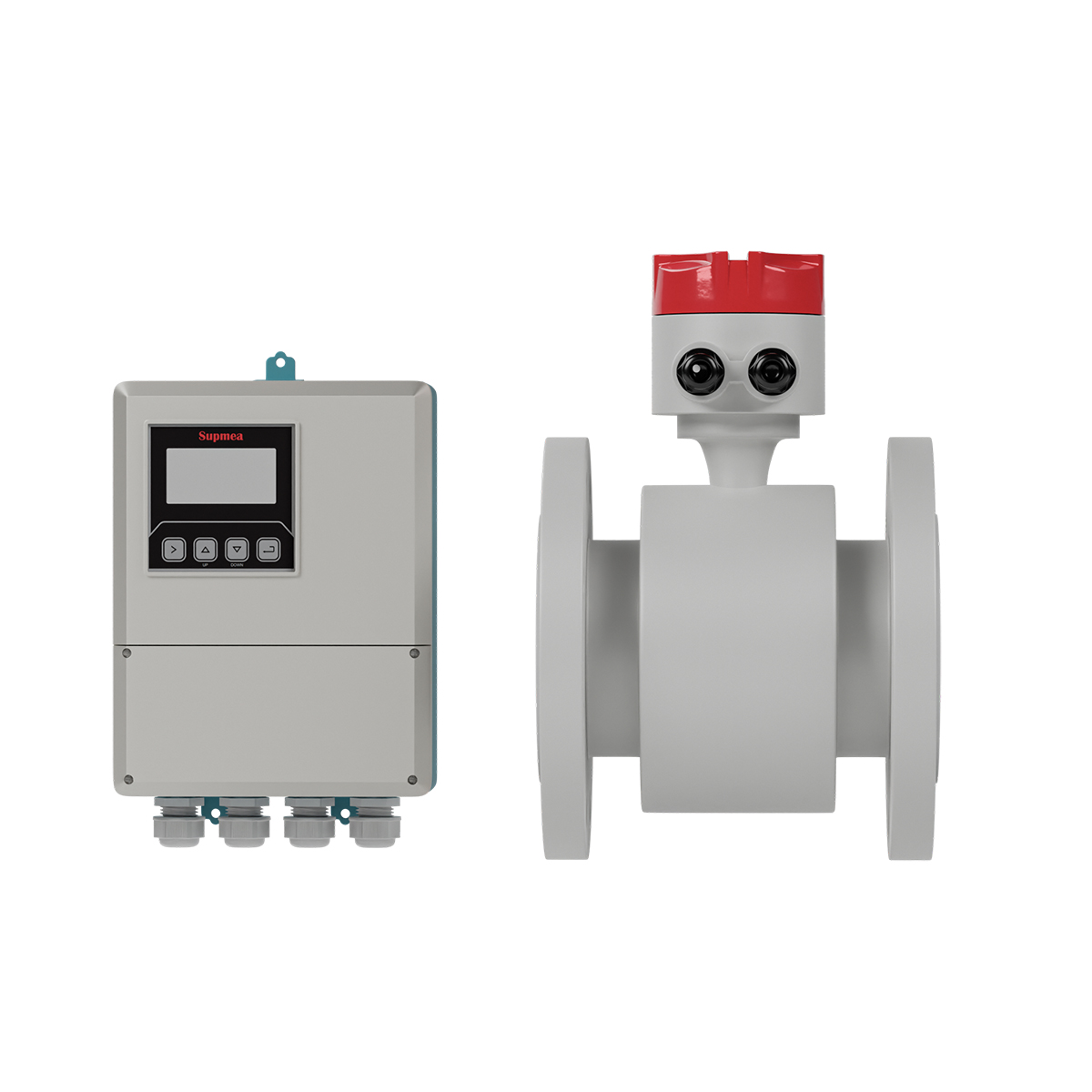

Second, a body type or split type selection

Electromagnetic Flowmeter has a one-piece and split type, one-piece generally used in good environmental conditions, one-piece electromagnetic sensor and converter is one. Split type is the sensor and converter is separate, generally not suitable for reading places such as the use of split type. For example: high ambient temperature, pipeline vibration, the site environment has corrosion, flowmeter installation location in the high altitude and so on. Such a case using split electromagnetic, with 10m cable to the converter, so that the converter in the appropriate environment.

Third, the sensor caliber selection

In general, consider the ease of installation, do not choose the reducer. But the premise is that the applicable flow rate in the flowmeter tube should be in the range of 0.3m/S ~ 10m/S. This choice is often applied to the new design of the project, in the selection of flow rate discipline to consider the current working conditions, but also to consider the future situation when the equipment is operating at full capacity. But sometimes also choose the caliber of the sensor is not the same as the caliber of the connected process piping. As follows:

(1) the flow rate in the pipeline is low, the process flow rate and more stable, in order to meet the requirements of the instrument on the flow rate range, in the flowmeter to locally increase the flow rate, select the sensor caliber is smaller than the caliber of the process pipeline, before and after the sensor to install a reducer.

(2) for large caliber Electromagnetic Flowmeter, the larger the caliber, the higher the price, the lower the flow rate in the pipeline, process parameters are stable, you can choose a smaller caliber flowmeter, which not only makes the flowmeter running in a better working condition, while reducing investment costs.

Fourth, the choice of electrode materials: 316L electrode, tantalum electrode, HC electrode, platinum electrode and so on.

Fifth, the choice of grounding ring material

Grounding ring material can be the same as the electrode material, generally can be selected with the same corrosion resistance of pipeline materials.

Sixth, the choice of lining materials

According to the media, you can choose: PO material, rubber material, PTFE material, polyurethane material, ceramic lining.

Related Products

Inquiry

Please leave us your requirements, we will contact you soon.