Analysis of the solution to the flange and valve failure of the magnetic flap level gauge

As a common liquid level measuring device, the magnetic flap level gauge is widely used in various industrial fields. However, during use, problems such as flange and valve failures are often encountered. This article will analyze the flange and valve failures of the magnetic flap level gauge and provide corresponding solutions.

First half of the content:

Loose flange sealing:

Loose flange sealing is one of the common problems of magnetic flap level gauges, which may This may cause liquid leakage or water intrusion, affecting the normal operation of the equipment.

Rust and corrosion at flange connections:

Due to long-term exposure to harsh environments, flange connections may rust and corrode, resulting in loose or damaged connections, which in turn affects the liquid level. Accuracy of measurement.

Valve blockage:

Valve blockage is another common problem. The valve may not be able to open or close normally due to suspended solids, sediments, etc. in the medium, affecting the operation of the liquid level meter. .

Insensitive valve action:

Insensitive valve action may be caused by damage to valve components, poor lubrication, etc., resulting in an inability to respond to liquid level changes in a timely manner.

Second half: related questions and answers

How to solve the problem of loose flange sealing?

Answer: It can be solved by replacing the sealing gasket and adjusting the flange bolt torque. Ensure flange connections are tightly sealed to prevent liquid leakage.

How to prevent rust and corrosion at flange connections?

Answer: Regularly inspecting and cleaning the flange connections, applying anti-rust lubricants, and using materials with good corrosion resistance to make flanges can extend the service life of the flanges.

What is the solution to a clogged valve?

Answer: The blockage can be removed and the normal operation of the valve can be restored by cleaning the valve, replacing valve parts, adding filters, etc.

How to deal with insensitive valve action?

Answer: It can be solved by lubricating the valve, replacing damaged parts, adjusting the valve actuator, etc. Ensure that the valve can respond sensitively to changes in liquid level and ensure the accuracy of the liquid level gauge.

Summary:

Flange and valve failures of the magnetic flap level gauge are important factors affecting the normal operation of the equipment. Through regular inspection, maintenance and timely troubleshooting, the stability and accuracy of the liquid level gauge can be guaranteed and the smooth progress of industrial production can be ensured.

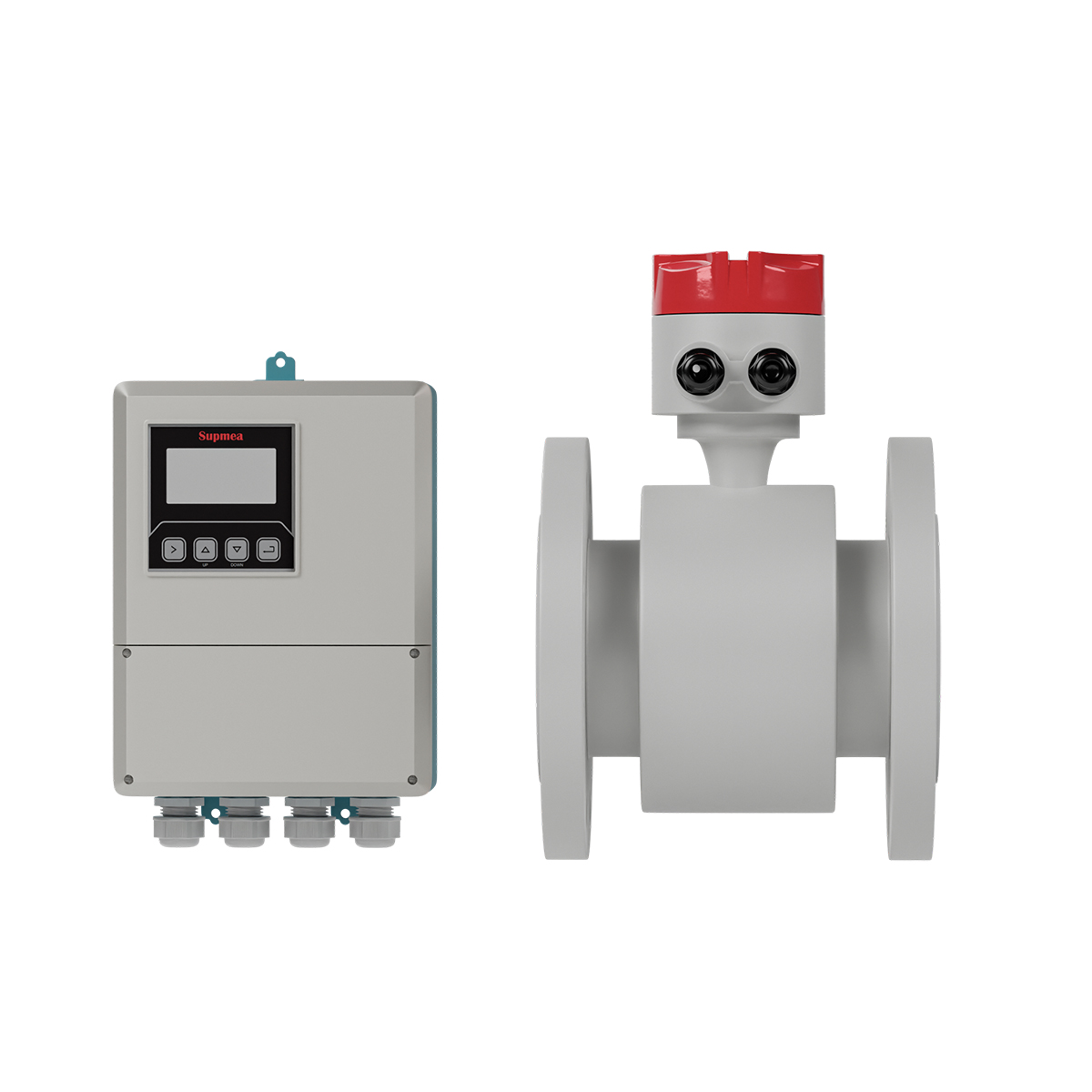

Related Products

Inquiry

Please leave us your requirements, we will contact you soon.