Don’t buy these 4 types of electromagnetic flow meters no matter how cheap they are!

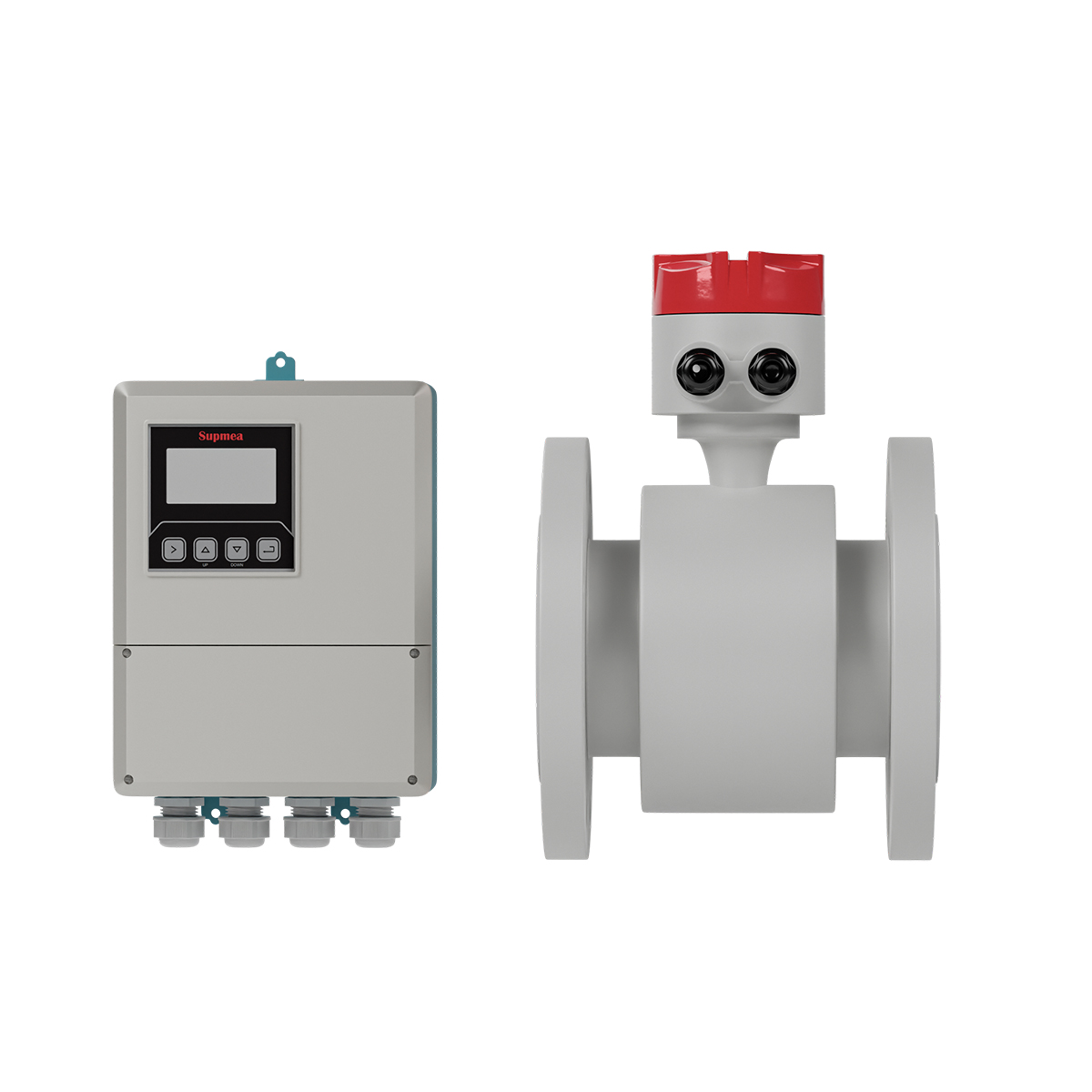

In the industrial field, Electromagnetic Flowmeter, as a common flow measurement equipment, is widely used in water treatment, chemical industry, petroleum and other industries. However, there are some low-priced Electromagnetic Flowmeter models on the market. They seem to be attractive in price, but their quality is not satisfactory. This article will explore the reasons why these four types of Electromagnetic Flowmeters cannot be purchased even if they are cheap.

First half of the content:

Low accuracy:

Low-price Electromagnetic Flowmeters usually use cheap sensors and electronic components, and their accuracy often cannot meet the requirements of industrial production. Require. Due to the low accuracy, there may be large deviations in the measurement results, which affects the control and optimization of the production process.

Instability:

Low-priced Electromagnetic Flowmeters often lack strict quality control during the design and manufacturing process, resulting in poor stability. In long-term use, problems such as drift and malfunction may occur, affecting the accuracy and reliability of flow measurement.

Easy to wear and tear:

Low-price Electromagnetic Flowmeters usually use cheap materials and processes, and have poor corrosion resistance and wear resistance. When dealing with corrosive media or in high-pressure and high-temperature environments, damage and water leakage are prone to occur, increasing maintenance and replacement costs.

Lack of after-sales service:

Low-priced Electromagnetic Flowmeters often come from small manufacturers or do not have a complete after-sales service system. Once quality problems occur or maintenance is needed, effective support may not be obtained in time. and solution, causing unnecessary trouble and losses to production.

Second half: Related questions and answers

How to identify low-priced Electromagnetic Flowmeters?

Answer: Pay attention to the brand, certification and technical parameters, choose manufacturers and products with good reputation and reliable quality, and avoid blindly pursuing low prices and neglecting quality.

What are the main quality problems of low-priced Electromagnetic Flowmeters?

Answer: The main problems include low accuracy, poor stability, easy loss, etc. These problems may lead to inaccurate measurement results, equipment failure and other serious consequences that affect production.

What should you pay attention to when choosing an Electromagnetic Flowmeter?

Answer: In addition to price, factors such as accuracy, stability, durability, and after-sales service also need to be considered to make a comprehensive evaluation to select the most suitable product.

How to effectively reduce the purchase cost of Electromagnetic Flowmeters?

Answer: The purchase cost of Electromagnetic Flowmeters can be effectively reduced by negotiating with manufacturers, purchasing in bulk, and selecting appropriate models, but you should not blindly pursue low prices and ignore quality.

Summary:

Although low-priced Electromagnetic Flowmeters seem attractive, their quality and performance often fail to meet the requirements of industrial production, which may cause serious consequences and losses. When choosing an Electromagnetic Flowmeter, you should fully consider the accuracy, stability, durability and other factors of the product, and choose reliable manufacturers and products to ensure the stability and safety of the production process.

Related Products

Inquiry

Please leave us your requirements, we will contact you soon.